Discover the key points about international manufacturing. What do you need to know about delegates your production with different suppliers? Which problems do you need to solve in the process?

Key aspects to choose the production center

Location of the production center

Local regulations can play a decisive role in selecting any option. The availability of raw materials, proximity to markets, skilled labor and guarantees of legal continuity are criteria that are generally taken into account. The location of the production center affects both production costs and logistics facilities, so it must be studied in detail.

Experience in the sector

The experience in the production sector ensures a very useful know-how for the client and speeds up the manufacturing processes.

Technology used and production process

It is convenient that the factory has modern technology and that there is ease of integration with the client’s systems.

Managed budget and possibility of adaptation

The price factor is decisive in defining the competitiveness of products in the market. For this reason, centers that adapt to the needs of the client are very valuable.

Transparency throughout the manufacturing process

It is important that the client is informed in real time of the manufacturing process of their products. This is one of the most important aspects, since other branches of the business usually depend on it.

Quality Standards, international manufacturing key point

When prioritizing one production center over another, it must be taken into account that it ensures certain previously agreed quality standards.

Choose the best production center in our platform

As always, PINEXPORTS is committed to digitization and innovation, offering a comprehensive solution for the control of international manufacturing. The EXHALE platform has business intelligence and machine learning technologies that, depending on the characteristics of the product and other variables previously defined by the client, obtain the best production center in each case. This saves time when placing orders and allows processes to be optimized, ensuring a very high quality standard. Our mission is to guarantee efficiency in each operation and achieve success for our clients.

On the other hand, all the suppliers we work with pass a quality control carried out by our experts on a constant basis.

Our quality control

At PINEXPORTS we carry out an exhaustive quality control with each of our suppliers.

The quality process is articulated based on the following key points:

- Factory audit. We audit and control the processes on site in each factory to ensure the quality of the final product.

- Pre-shipment inspection. Before shipment, every detail is inspected to avoid errors.

- Inspection during the production process in each factory. The production process is monitored and the customer is informed of the status of their order in real time.

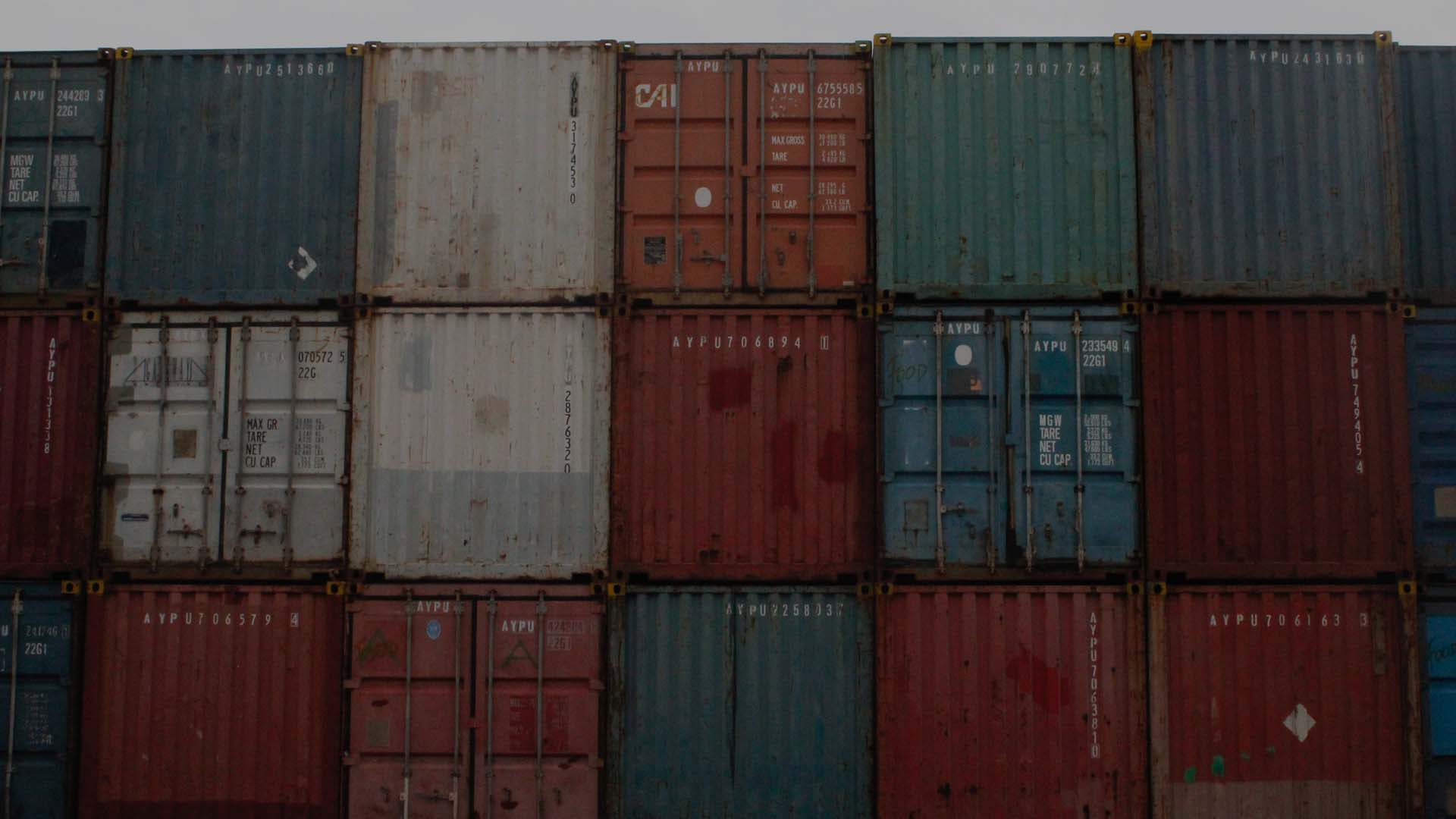

- Supervision of the loading process in the containers. An exhaustive control of container loading is carried out in each port. In this way, possible incidents are avoided and it is ensured that the order reaches its destination in the agreed conditions.

If you have questions about the international manufacturing process, contact us without any obligation.