International manufacturing presents both opportunities and challenges. As companies expand their reach beyond borders, optimizing the supply chain becomes essential to ensure efficiency, quality, and profitability. In this article, we will explore five key strategies that can help international manufacturing companies optimize their supply chain and achieve success in a highly competitive global market.

Production deadlines

Problem: Variability in delivery times.

Solution: Implement effective inventory management.

Variability in delivery times can negatively impact the supply chain, causing production delays and lost sales. An effective solution is to implement efficient inventory management. This involves maintaining adequate inventory levels by utilizing tools such as demand analysis, production planning, and market trend monitoring. Additionally, establishing strong relationships with reliable suppliers and maintaining open communication can reduce response times and minimize risks associated with delivery time variability.

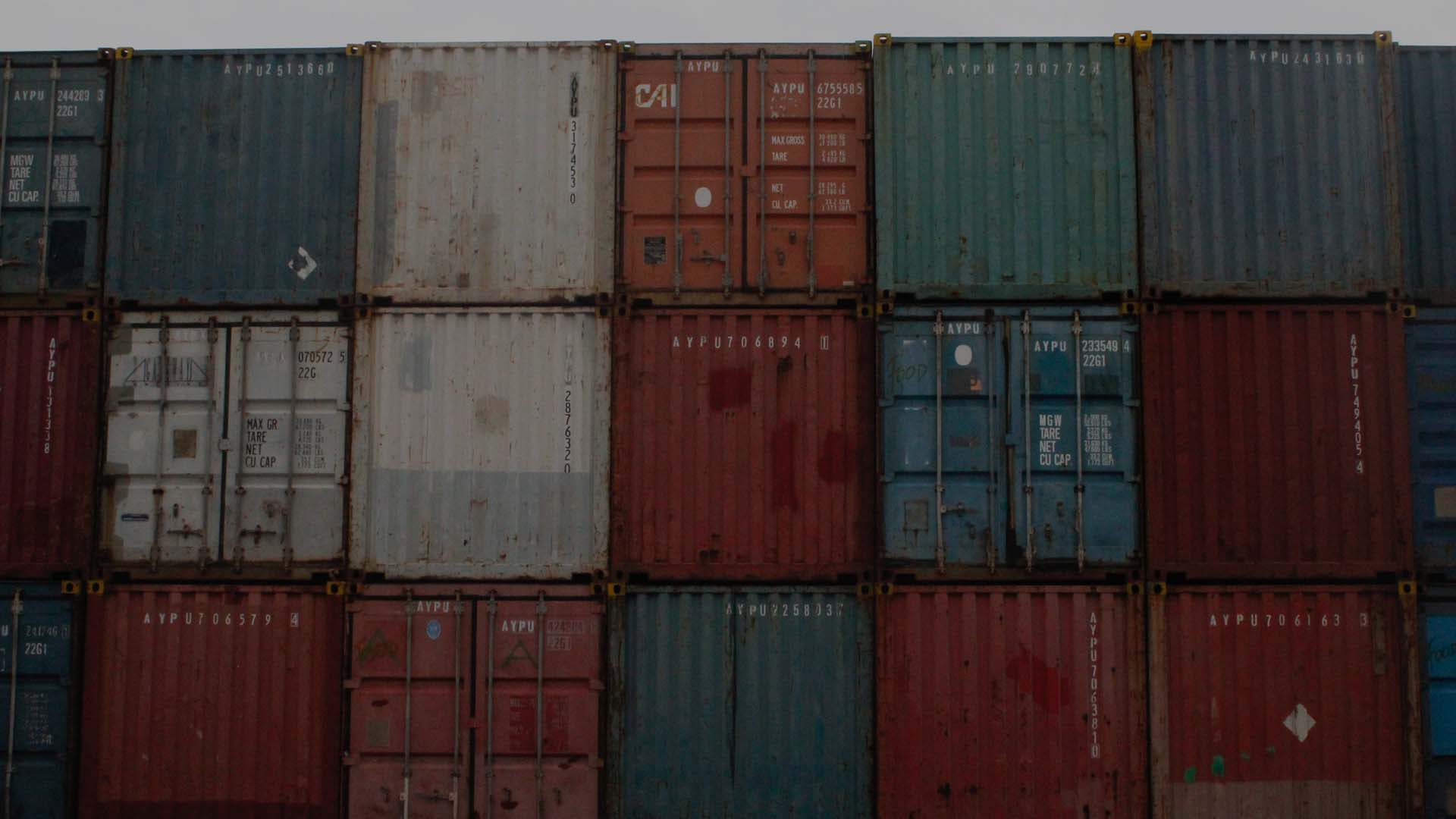

Save on transport and logistics costs

Problem: High transportation and logistics costs.

Solution: Optimize supplier selection and shipping routes.

High transportation and logistics costs can significantly impact the profitability of international manufacturing. To overcome this challenge, it is crucial to optimize supplier selection and shipping routes. Identifying suppliers that offer competitive prices and quality services can help reduce costs. Furthermore, evaluating and selecting the most efficient shipping routes in terms of time and cost can help minimize logistics expenses and enhance supply chain agility.

How to comply with quality standards and regulations in international production

Problem: Difficulty in meeting quality standards and international regulations.

Solution: Establish a quality control and regulatory compliance system.

Complying with quality standards and international regulations is crucial in international manufacturing. To address this issue, it is essential to establish a robust quality control and regulatory compliance system. This involves implementing comprehensive inspection and testing processes, ensuring suppliers meet required standards, and staying updated on relevant regulations. Additionally, fostering a culture of quality throughout the supply chain and providing training to personnel on specific requirements can contribute to ensuring compliance and customer satisfaction.

How to achieve visibility and coordinate the supply chain

Problem: Lack of visibility and coordination in the supply chain.

Solution: Utilize supply chain management technology.

The lack of visibility and coordination in the supply chain can lead to inefficiencies and delays. To overcome this obstacle, it is recommended to leverage supply chain management technology. Implementing advanced software systems that enable real-time tracking of processes, sharing relevant information among stakeholders, and facilitating data-driven decision-making can enhance visibility and coordination. Additionally, adopting solutions such as barcoding, RFID (Radio Frequency Identification), and process automation can optimize supply chain efficiency and agility.

How to adapt to market demands

Problem: Inflexibility to adapt to demand changes.

Solution: Implement an agile production strategy.

Lack of flexibility in international manufacturing can result in difficulties in adapting to market demand changes. An effective solution is to implement an agile production strategy. This involves having the capability to quickly adjust production volumes, working closely with suppliers to accelerate lead times, and adopting flexible manufacturing methods such as on-demand production. Additionally, establishing effective communication with customers and gathering market trend data can enable swift and timely responses to demand changes.

Optimizing the supply chain in international manufacturing is vital to achieving success in the global business landscape. By addressing key challenges such as variability in delivery times, high transportation and logistics costs, compliance with quality standards and regulations, lack of visibility and coordination, and inflexibility, companies can enhance efficiency, quality, and profitability. By adopting these key strategies and leveraging available technology, international manufacturing companies can ensure they are well-prepared to compete in an ever-evolving global market.